Self Piercing Screws

What You'll Find Here:

One of the largest selections of self-piercing screws on the planet!

Concise summary of all the options from head to point.

ScrooFinder– browse or add items to quote cart using our lightning fast parametric search engine.

Our online quoting process is also easy and intuitive for your convenience. Simply add the fasteners that you are interested in, to your cart, and then check out to receive a free quote.

If you're not sure what you need, you can call or email us for friendly, professional advice.

Self-piercing screws are also known as zip, needlepoint, saber point, sprint point, speed point or twinfast screws.

They are essentially self-tapping screws with a very sharp point that can pierce through thin gauge sheetmetal. The most common self-piercing screw has a twin lead thread with the first thread rolled to the tip of an extra sharp point, and a second thread starting just above it. As the screw pierces and turns into the metal the two threads instantly engage and drive the screw through the layers of sheetmetal with great ease & speed.

Self-Piercing Screws

Point Types | |

|---|---|

| Sharp Point | Type 17 Point |

|  |

Head & Drive Types | |||

|---|---|---|---|

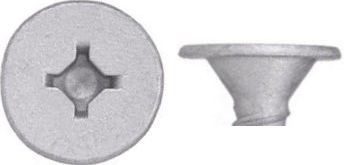

| Indented Hex Washer | Indented Hex Washer Slotted | Modified Truss Phil | |

|  |  | |

| Pan Square | Pan Framing Phil with Serrations | Pancake Phil/Square |

|  |  |

| Wafer Phil/Square |

|

Metal & Finish Types | |||

|---|---|---|---|

| Carbon Steel Zinc Plated | Carbon Steel Black Phosphate | Carbon Steel Ceramic Silver 1000HR | |

|  |  | |

| Carbon Steel Ceramic White 1000HR | 410 Stainless Dacromet 1000HR | 410 Stainless Passivated |

|  |  |

| 410 Stainless Copper Plated | 18-8 Stainless Plain | 18-8 Stainless Copper Plated |

|  |  |

| 305 Stainless Plain | Copper Plain |

|  |

Thread Types | |

|---|---|

| Single Lead/Fine Thread | Twin Lead/Full Thread |

|  |

| Twin Lead/Partial Thread | Twin Lead/Hi-Lo Thread |

|  |

| Unit of Measure: M = 1000 | |

| Request # of screws | Enter |

| 15,000 | 15 |

| 1,255 | 1.255 |

| 5 | 0.005 |

- 1000H1S0606

- #6-18 X 3/8 Self-Piercing Screws, 1/4" Indented Hex Washer Head Slotted, Carbon Steel, Zinc Plated

- B

- 0

- Weight: 2.2

| Diameter/Size: | #6#6 |

| Length: | 3/8"3/8" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 20.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0616

- #6-18 X 1 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- E

- 0

- Weight: 4.0

| Diameter/Size: | #6#6 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 6.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0708

- #7-16 X 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- D

- 0

- Weight: 2.5

| Diameter/Size: | #7#7 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0709

- #7-16 X 9/16 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 2.4

| Diameter/Size: | #7#7 |

| Length: | 9/16"9/16" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 16.000 M

- Min Order Qty: 16.000 M

- UM: M

- 1000H1S0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- A

- 0

- Weight: 3.1

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0809

- #8-15 X 9/16 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- D

- 0

- Weight: 3.2

| Diameter/Size: | #8#8 |

| Length: | 9/16"9/16" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 14.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0810

- #8-15 X 5/8 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 3.4

| Diameter/Size: | #8#8 |

| Length: | 5/8"5/8" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 12.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0812

- #8-15 X 3/4 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 3.9

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0816

- #8-15 X 1 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 4.7

| Diameter/Size: | #8#8 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0820

- #8-15 X 1-1/4 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- C

- 0

- Weight: 5.8

| Diameter/Size: | #8#8 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 7.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0824

- #8-15 X 1-1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 6.8

| Diameter/Size: | #8#8 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 6.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1S0832

- #8-15 X 2 Self-Piercing Screws, 1/4" IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 8.7

| Diameter/Size: | #8#8 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1U0606

- #6-18 X 3/8 Self-Piercing Screws, 1/4" IHWH Unslotted, Steel Zinc Plated

- E

- 0

- Weight: 2.4

| Diameter/Size: | #6#6 |

| Length: | 3/8"3/8" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" IHWH Unslot1/4" IHWH Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 20.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H1U0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" IHWH Unslotted, Steel Zinc Plated

- G

- 0

- Weight: 3.0

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" IHWH Unslot1/4" IHWH Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H2S0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" Tall IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 3.2

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Tall Slot1/4" IHWH Tall Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H2U0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Steel Zinc Plated

- B

- 0

- Weight: 3.3

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" IHWH Tall Unslot1/4" IHWH Tall Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 14.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H3S1008

- #10-12 X 1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Steel Zinc Plated

- D

- 0

- Weight: 4.3

| Diameter/Size: | #10#10 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H3S1012

- #10-12 X 3/4 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Steel Zinc Plated

- C

- 0

- Weight: 5.8

| Diameter/Size: | #10#10 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 8.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H3S1016

- #10-12 X 1 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Steel Zinc Plated

- B

- 0

- Weight: 6.7

| Diameter/Size: | #10#10 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H3S1020

- #10-12 X 1-1/4 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Steel Zinc Plated

- D

- 0

- Weight: 8.0

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H3S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Steel Zinc Plated

- E

- 0

- Weight: 9.2

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1020

- #10-12 X 1-1/4 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- C

- 0

- Weight: 7.3

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- A

- 0

- Weight: 9.1

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1032

- #10-12 X 2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- B

- 0

- Weight: 12.2

| Diameter/Size: | #10#10 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1040

- #10-12 X 2-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- B

- 0

- Weight: 14.4

| Diameter/Size: | #10#10 |

| Length: | 2 1/2"2 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1048

- #10-12 X 3 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- B

- 0

- Weight: 17.3

| Diameter/Size: | #10#10 |

| Length: | 3"3" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1056

- #10-12 X 3-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- D

- 0

- Weight: 19.6

| Diameter/Size: | #10#10 |

| Length: | 3 1/2"3 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 1.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1064

- #10-12 X 4 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- C

- 0

- Weight: 22.4

| Diameter/Size: | #10#10 |

| Length: | 4"4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 1.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H4S1224

- #12-11 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Zinc Plated

- C

- 0

- Weight: 12.7

| Diameter/Size: | #12#12 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.200 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1008

- #10-12 X 1/2 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 5.1

| Diameter/Size: | #10#10 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1012

- #10-12 X 3/4 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- E

- 0

- Weight: 5.8

| Diameter/Size: | #10#10 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 8.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1016

- #10-12 X 1 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- D

- 0

- Weight: 7.4

| Diameter/Size: | #10#10 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 6.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1020

- #10-12 X 1-1/4 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- E

- 0

- Weight: 8.9

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 3.000 M

- UM: M

- 1000H6S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- E

- 0

- Weight: 10.0

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1032

- #10-12 X 2 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 11.7

| Diameter/Size: | #10#10 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.000 M

- Min Order Qty: 2.000 M

- UM: M

- 1000H6S1048

- #10-12 X 3 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 16.3

| Diameter/Size: | #10#10 |

| Length: | 3"3" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 1.500 M

- Min Order Qty: 2.000 M

- UM: M

- 1000H6S1216

- #12-11 X 1 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 9.3

| Diameter/Size: | #12#12 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1224

- #12-11 X 1 1/2 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 12.2

| Diameter/Size: | #12#12 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1232

- #12-11 X 2 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 15.8

| Diameter/Size: | #12#12 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6S1248

- #12-11 X 3 Self-Piercing Screws, 5/16" IHWH Slotted, Steel Zinc Plated

- G

- 0

- Weight: 23.0

| Diameter/Size: | #12#12 |

| Length: | 3"3" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" IHWH Slot5/16" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 1.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6U1020

- #10-12 X 1-1/4 Self-Piercing Screws, 5/16" IHWH Unslotted, Steel Zinc Plated

- G

- 0

- Weight: 8.9

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | HexHex |

| Head/Drive Detail: | 5/16" IHWH Unslot5/16" IHWH Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H6U1032

- #10-12 X 2 Self-Piercing Screws, 5/16" IHWH Unslotted, Steel Zinc Plated

- G

- 0

- Weight: 11.7

| Diameter/Size: | #10#10 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | HexHex |

| Head/Drive Detail: | 5/16" IHWH Unslot5/16" IHWH Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H7S1012

- #10-12 X 3/4 Self-Piercing Screws, 5/16" Tall IHWH Slotted, Steel Zinc Plated

- C

- 0

- Weight: 6.2

| Diameter/Size: | #10#10 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" Tall IHWH Slot5/16" Tall IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 7.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H7S1016

- #10-12 X 1 Self-Piercing Screws, 5/16" Tall IHWH Slotted, Steel Zinc Plated

- B

- 0

- Weight: 7.4

| Diameter/Size: | #10#10 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" Tall IHWH Slot5/16" Tall IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 6.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H7S1020

- #10-12 X 1-1/4 Self-Piercing Screws, 5/16" Tall IHWH Slotted, Steel Zinc Plated

- C

- 0

- Weight: 8.9

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" Tall IHWH Slot5/16" Tall IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H7S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 5/16" Tall IHWH Slotted, Steel Zinc Plated

- D

- 0

- Weight: 10.0

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" Tall IHWH Slot5/16" Tall IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000H7S1032

- #10-12 X 2 Self-Piercing Screws, 5/16" Tall IHWH Slotted, Steel Zinc Plated

- D

- 0

- Weight: 11.7

| Diameter/Size: | #10#10 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 5/16" Tall IHWH Slot5/16" Tall IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0808

- #8-15 X 1/2 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- C

- 0

- Weight: 3.5

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 0.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0809

- #8-15 X 9/16 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- E

- 0

- Weight: 3.8

| Diameter/Size: | #8#8 |

| Length: | 9/16"9/16" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 12.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0812

- #8-15 X 3/4 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- B

- 0

- Weight: 4.5

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0816

- #8-15 X 1 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- B

- 0

- Weight: 5.6

| Diameter/Size: | #8#8 |

| Length: | 1"1" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 7.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0820

- #8-15 X 1-1/4 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- B

- 0

- Weight: 5.7

| Diameter/Size: | #8#8 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 8.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0824

- #8-15 X 1-1/2 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- C

- 0

- Weight: 7.0

| Diameter/Size: | #8#8 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0826

- #8-15 X 1-5/8 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- E

- 0

- Weight: 7.6

| Diameter/Size: | #8#8 |

| Length: | 1 5/8"1 5/8" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0830

- #8-15 X 1-7/8 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- G

- 0

- Weight: 7.8

| Diameter/Size: | #8#8 |

| Length: | 1 7/8"1 7/8" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0832

- #8-15 X 2 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- C

- 0

- Weight: 9.0

| Diameter/Size: | #8#8 |

| Length: | 2"2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0840

- #8-15 X 2-1/2 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- C

- 0

- Weight: 10.4

| Diameter/Size: | #8#8 |

| Length: | 2 1/2"2 1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000MTP0848

- #8-15 X 3 Self-Piercing Screws, Modified Truss Head Phillips, Steel Zinc Plated

- D

- 0

- Weight: 12.0

| Diameter/Size: | #8#8 |

| Length: | 3"3" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N1S0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Sealing Washer, Steel Zinc Plated

- G

- 0

- Weight: 5.5

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot/EPDM Bond Washer1/4" IHWH Slot/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 7.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N1S0812

- #8-15 X 3/4 Self-Piercing Screws, 1/4" IHWH Slotted, Sealing Washer, Steel Zinc Plated

- G

- 0

- Weight: 5.5

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot/EPDM Bond Washer1/4" IHWH Slot/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 4.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N1S0816

- #8-15 X 1 Self-Piercing Screws, 1/4" IHWH Slotted, Sealing Washer, Steel Zinc Plated

- G

- 0

- Weight: 7.0

| Diameter/Size: | #8#8 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot/EPDM Bond Washer1/4" IHWH Slot/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N1S0824

- #8-15 X 1 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Sealing Washer, Steel Zinc Plated

- G

- 0

- Weight: 8.2

| Diameter/Size: | #8#8 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot/EPDM Bond Washer1/4" IHWH Slot/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N1S0832

- #8-15 X 1 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Sealing Washer, Steel Zinc Plated

- G

- 0

- Weight: 10.8

| Diameter/Size: | #8#8 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot/EPDM Bond Washer1/4" IHWH Slot/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 2.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000N4S1056

- #10-12 X 3-1/2 Self-Piercing Screws, 1/4" Tall IHWH Slotted, Fillet, Sealing Washer, Steel Zinc Pltd

- G

- 0

- Weight: 22.0

| Diameter/Size: | #10#10 |

| Length: | 3 1/2"3 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/Fillet/EPDM Bond Washer1/4" Tall IHWH Slot/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 0.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000PFP0607

- #6-18 X 7/16 Self-Piercing Screws, Pan Head Framing Phillips, Steel Zinc Plated

- D

- 0

- Weight: 2.3

| Diameter/Size: | #6#6 |

| Length: | 7/16"7/16" |

| Head Type: | Pan FramingPan Framing |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Pan Framing Phil/SerrationsPan Framing Phil/Serrations |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1000UTQ0812

- #8-15 X 3/4 Self-Piercing Screws, Ultra-Wide Modified Truss Head Philllips/Square, Steel Zinc Plated

- G

- 0

- Weight: 5.4

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Ultra-Wide Modified TrussUltra-Wide Modified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Phillips/SquarePhillips/Square |

| Head/Drive Detail: | Ultra-Wide Modified Truss Phillips/SquareUltra-Wide Modified Truss Phillips/Square |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 8.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000UTQ0816

- #8-15 X 1" Self-Piercing Screws, Ultra-Wide Modified Truss Head Philllips/Square, Steel Zinc Plated

- G

- 0

- Weight: 6.2

| Diameter/Size: | #8#8 |

| Length: | 1"1" |

| Head Type: | Ultra-Wide Modified TrussUltra-Wide Modified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Phillips/SquarePhillips/Square |

| Head/Drive Detail: | Ultra-Wide Modified Truss Phillips/SquareUltra-Wide Modified Truss Phillips/Square |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 7.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1000UTQ0820

- #8-15 X 1-1/4" Self-Piercing Screws, Ultra-Wide Modified Truss Head Philllips/Square, Steel Zinc

- G

- 0

- Weight: 7.1

| Diameter/Size: | #8#8 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Ultra-Wide Modified TrussUltra-Wide Modified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Zinc PlatedZinc Plated |

| DriveType: | Phillips/SquarePhillips/Square |

| Head/Drive Detail: | Ultra-Wide Modified Truss Phillips/SquareUltra-Wide Modified Truss Phillips/Square |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 6.500 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0808

- #8-15 X 1/2 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- D

- 0

- Weight: 3.5

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0809

- #8-15 X 9/16 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 3.8

| Diameter/Size: | #8#8 |

| Length: | 9/16"9/16" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0812

- #8-15 X 3/4 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 5.6

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0816

- #8-15 X 1 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- E

- 0

- Weight: 5.6

| Diameter/Size: | #8#8 |

| Length: | 1"1" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 8.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0820

- #8-15 X 1-1/4 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 6.4

| Diameter/Size: | #8#8 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 8.000 M

- UM: M

- 100PMTP0824

- #8-15 X 1-1/2 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 7.0

| Diameter/Size: | #8#8 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0826

- #8-15 X 1-5/8 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- D

- 0

- Weight: 7.6

| Diameter/Size: | #8#8 |

| Length: | 1 5/8"1 5/8" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0830

- #8-15 X 1-7/8 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 7.8

| Diameter/Size: | #8#8 |

| Length: | 1 7/8"1 7/8" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 3.000 M

- UM: M

- 100PMTP0832

- #8-15 X 2 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 8.7

| Diameter/Size: | #8#8 |

| Length: | 2"2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0840

- #8-15 X 2-1/2 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 10.4

| Diameter/Size: | #8#8 |

| Length: | 2 1/2"2 1/2" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.500 M

- Min Order Qty: 0.100 M

- UM: M

- 100PMTP0848

- #8-15 X 3 Self-Piercing Screws, Modified Truss Head Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 12.0

| Diameter/Size: | #8#8 |

| Length: | 3"3" |

| Head Type: | Modified TrussModified Truss |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Modified Truss PhilModified Truss Phil |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.000 M

- Min Order Qty: 2.000 M

- UM: M

- 100PPFP0607

- #6-18 X 7/16 Self-Piercing Screws, Pan Head Framing Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 2.3

| Diameter/Size: | #6#6 |

| Length: | 7/16"7/16" |

| Head Type: | Pan FramingPan Framing |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Pan Framing Phil/SerrationsPan Framing Phil/Serrations |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 10.000 M

- UM: M

- 100PPFP0707

- #7-16 X 7/16 Self-Piercing Screws, Pan Head Framing Phillips, Carbon Steel, Black Phosphate

- G

- 0

- Weight: 2.6

| Diameter/Size: | #7#7 |

| Length: | 7/16"7/16" |

| Head Type: | Pan FramingPan Framing |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Black PhosphateBlack Phosphate |

| DriveType: | PhillipsPhillips |

| Head/Drive Detail: | Pan Framing Phil/SerrationsPan Framing Phil/Serrations |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H1S0606

- #6-18 X 3/8 Self-Piercing Screws, 1/4" IHWH Slotted, Carbon Steel, Ceramic White 1000 Hr

- C

- 0

- Weight: 2.0

| Diameter/Size: | #6#6 |

| Length: | 3/8"3/8" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 20.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H1S0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Carbon Steel, Ceramic White 1000 Hr

- B

- 0

- Weight: 3.1

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 15.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H1S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 1/4" IHWH Slotted, Carbon Steel, Ceramic White 1000 Hr

- G

- 0

- Weight: 8.5

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" IHWH Slot1/4" IHWH Slot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H2U0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Carbon Steel, Ceramic White 1000 Hr

- B

- 0

- Weight: 3.3

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" IHWH Tall Unslot1/4" IHWH Tall Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 12.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H2U0812

- #8-15 X 3/4 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Carbon Steel, Ceramic White 1000 Hr

- C

- 0

- Weight: 4.0

| Diameter/Size: | #8#8 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" IHWH Tall Unslot1/4" IHWH Tall Unslot |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 10.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H3S1016

- #10-12 X 1 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Carbon Steel, Ceramic White

- E

- 0

- Weight: 6.6

| Diameter/Size: | #10#10 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer1/4" Tall IHWH Slot/#10 Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 0.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H4S1020

- #10-12 X 1-1/4 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Ceramic White

- D

- 0

- Weight: 8.3

| Diameter/Size: | #10#10 |

| Length: | 1 1/4"1 1/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 5.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H4S1024

- #10-12 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Ceramic White

- B

- 0

- Weight: 9.6

| Diameter/Size: | #10#10 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1010H4S1032

- #10-12 X 2 Self-Piercing Screws, 1/4" Tall IHWH Wide Washer Slotted, Fillet, Steel Ceramic White

- C

- 0

- Weight: 12.2

| Diameter/Size: | #10#10 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic White 1000HrCeramic White 1000Hr |

| DriveType: | Hex/SlottedHex/Slotted |

| Head/Drive Detail: | 1/4" Tall IHWH Slot/#10 Washer/Fillet1/4" Tall IHWH Slot/#10 Washer/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 0.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011H5U0916

- #9-15 X 1 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Carbon Steel, Ceram Silver 1000Hr

- C

- 0

- Weight: 6.4

| Diameter/Size: | #9#9 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unslot/Fillet1/4" Tall IHWH Unslot/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 7.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011H5U0924

- #9-15 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Steel Ceramic Silver 1000 Hr

- C

- 0

- Weight: 8.6

| Diameter/Size: | #9#9 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unslot/Fillet1/4" Tall IHWH Unslot/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 4.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011H5U0932

- #9-15 X 2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Steel Ceramic Silver 1000 Hr

- D

- 0

- Weight: 11.0

| Diameter/Size: | #9#9 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unslot/Fillet1/4" Tall IHWH Unslot/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 3.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011H5U0940

- #9-15 X 2-1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Steel Ceramic Silver 1000 Hr

- D

- 0

- Weight: 13.0

| Diameter/Size: | #9#9 |

| Length: | 2 1/2"2 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unslot/Fillet1/4" Tall IHWH Unslot/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 2.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011H5U0948

- #9-15 X 3 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Steel Ceramic Silver 1000 Hr

- C

- 0

- Weight: 15.5

| Diameter/Size: | #9#9 |

| Length: | 3"3" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unslot/Fillet1/4" Tall IHWH Unslot/Fillet |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | NoNo |

- Full Carton Qty: 1.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U0916

- #9-15 X 1 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Sealing Washer, Steel Ceram Silver

- B

- 0

- Weight: 7.7

| Diameter/Size: | #9#9 |

| Length: | 1"1" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 6.000 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U0924

- #9-15 X 1-1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslot, Fillet, Sealing Wsher, Steel Ceram Silver

- A

- 0

- Weight: 10.8

| Diameter/Size: | #9#9 |

| Length: | 1 1/2"1 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 4.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U0932

- #9-15 X 2 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Sealing Washer, Steel Ceram Silver

- B

- 0

- Weight: 12.3

| Diameter/Size: | #9#9 |

| Length: | 2"2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 3.500 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U0940

- #9-15 X 2-1/2 Self-Piercing Screws, 1/4" Tall IHWH Unslot, Fillet, Sealing Wsher, Steel Ceram Silver

- C

- 0

- Weight: 14.5

| Diameter/Size: | #9#9 |

| Length: | 2 1/2"2 1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 3.200 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U0948

- #9-15 X 3 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Sealing Washer, Steel Ceram Silver

- B

- 0

- Weight: 16.7

| Diameter/Size: | #9#9 |

| Length: | 3"3" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 0.900 M

- Min Order Qty: 0.100 M

- UM: M

- 1011N5U1212

- #12-14 X 3/4 Self-Piercing Screws, 1/4" Tall IHWH Unslotted, Fillet, Sealing Wsher, Steel Ceram Silv

- D

- 0

| Diameter/Size: | #12#12 |

| Length: | 3/4"3/4" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | Carbon SteelCarbon Steel |

| Finish Type: | Ceramic Silver 1000HrCeramic Silver 1000Hr |

| DriveType: | HexHex |

| Head/Drive Detail: | 1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer1/4" Tall IHWH Unsl/Fillet/EPDM Bond Washer |

| Thread Type: | Twin Lead/Full ThreadTwin Lead/Full Thread |

| Point Type: | Sharp PointSharp Point |

| Origin: | ImportedImported |

| Sealing Washer Fitted: | YesYes |

- Full Carton Qty: 5.000 M

- Min Order Qty: 5.000 M

- UM: M

- 10CUH1U0808

- #8-15 X 1/2 Self-Piercing Screws, 1/4" IHWH Unslotted, Solid Copper, Plain

- C

- 0

- Weight: 3.0

| Diameter/Size: | #8#8 |

| Length: | 1/2"1/2" |

| Head Type: | Hex WasherHex Washer |

| Metal Type: | CopperCopper |